Basic Info.

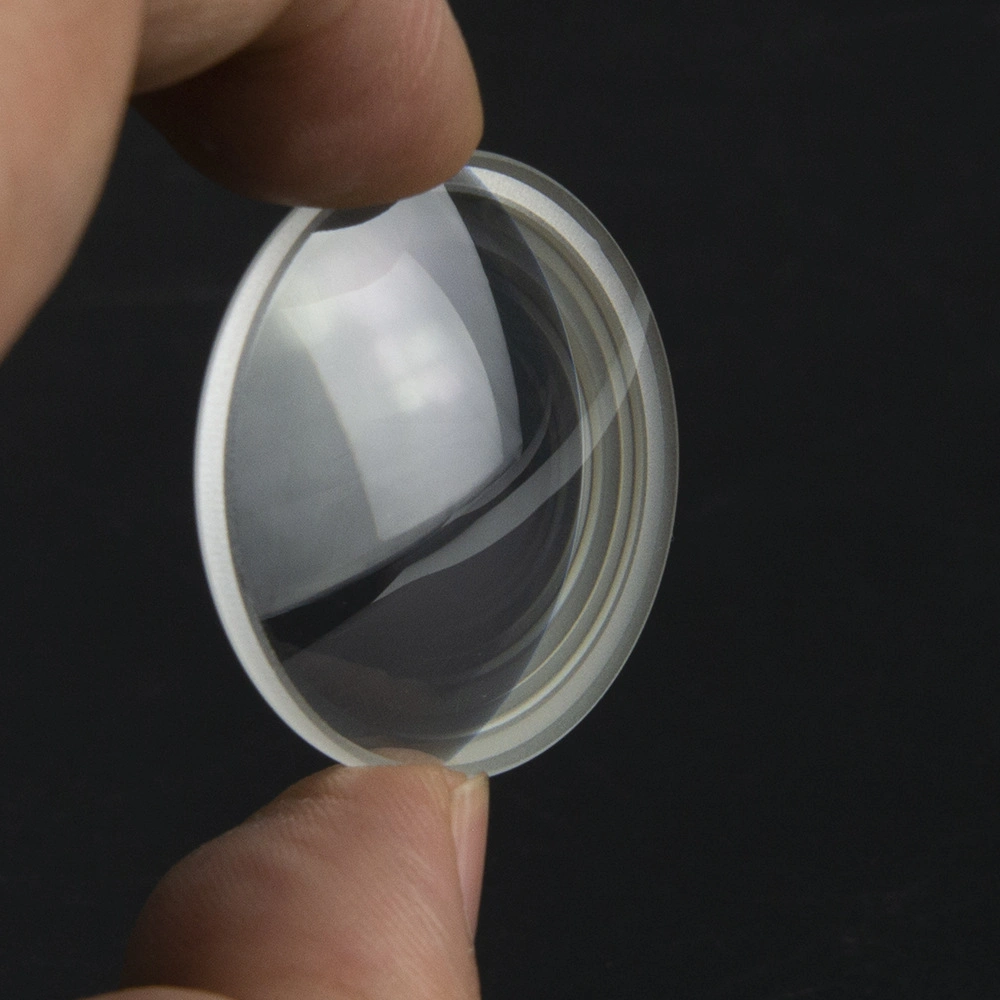

Product Description

Here provide all kinds of customized optical lens which according to your drawings, sample products or detailed requirements. Any inquiry please feel free to contact us, thanks!

| Size | Φ1.0~7mm | Φ8.0~20mm | Φ20.0~40mm | Φ40.0~60mm |

| PV | 0.2um | 0.3um | 0.5um | <1um |

| Eccentricity | <=3um | <=5um | <=5um | <=8um |

| Center Thickness Tolerance | ±0.015mm | ±0.020mm | ±0.025mm | ±0.050mm |

| Diameter Tolerance | ±0.015mm | ±0.015mm | ±0.015mm | ±0.030mm |

| Surface Quality | 40/20 | |||

| Surface Roughness | >20nm | |||

| RMS | According to the optical system | |||

| Material | CDGM, NHG, customer Requirements | |||

Small aspheric glass lenses can be made by molding, which allows cheap mass production. Due to their low cost and good performance, molded aspheres are commonly used in inexpensive consumer cameras, camera phones, and CD players.They are also commonly used for laser diode collimation, and for coupling light into and out of optical fibers.

Larger aspheres are made by grinding and polishing. Lenses produced by these techniques are used in telescopes, projection TVs, missile guidance systems, and scientific research instruments. They can be made by point-contact contouring to roughly the right form which is then polished to its final shape. In other designs, such as the Schmidt systems, the aspheric corrector plate can be made by using a vacuum to distort an optically parallel plate into a curve which is then polished "flat" on one side. Aspheric surfaces can also be made by polishing with a small tool with a compliant surface that conforms to the optic, although precise control of the surface form and quality is difficult, and the results may change as the tool wears.

Aspherical Lenses

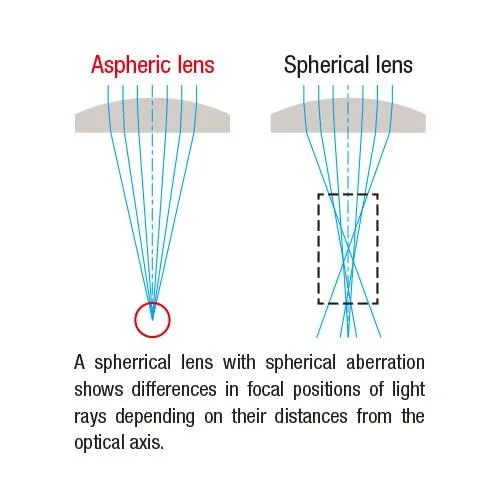

Aspheric Lenses are used to eliminate spherical aberration in a range of applications, including bar code scanners, laser diode collimation, or OEM or R&D integration. Aspheric lenses utilize a single element design which helps minimize the number of lenses found in multi-lens optical assemblies.

Products are widely used in optical equipment, teaching, industrial lenses, camera, video shooting, automation, medical, measuring and surveying equipment, aviation, astronomy, etc.. So it requires different materials for different work range.Our products cover ultraviolet, visible light and infrared band.

A sphere is defined by a single radius of curvature. Aspheric Lens have at least one aspherical surface. Optical engineers generally think of aspheric surfaces as aspheric, rotationally symmetric surfaces. The radius of curvature of the aspheric surface varies gradually from the center of the lens to the edge.

The surface profiles of aspheric lenses are not a portion of a sphere or cylinder. Their curvature radius varies with the central axis. Aspheric lenses have unique advantages over spherical lenses. For example, they can improve optical quality, reduce optical components and design costs. They are widely used in optical instruments, images and optoelectronics industries, such as digital cameras, CD players and high-end microscopic instruments.

Difference between aspheric lenses & spherical lenses:

Aspheric Lenses: Advantages & Disadvantages In a nutshell, aspheric lenses have the following advantages:

They provide a thinner profile

They are lightweight and comfortable

They could be fit into most frames so you have a wide choice of styles

They have a more natural and pleasing appearance

They don't make your eyes look too big or too small

They provide a better peripheral vision by eliminating distortion

Cylindrical lens is used to correct astigmatism in the optical system, and, in rangefinders, to produce astigmatism, stretching a point of light into a line. It is usually used in barcode scanners, objective systems and other optical systems.

Feature:

1 . Correcting Astigmatism

One of the main applications of cylindrical lenses is in ophthalmology, specifically, to correct astigmatic vision. When a person presents astigmatic vision, it is usually the result of a corneal deformation. An astigmatic cornea will have different focal points at different axes. It is then possible to use a cylindrical lens to change the focal point of one of the axes to overlap the second one.

2 . Laser Line Scanning

This is a technique that is used to capture the shape of a 3D object into a digital copy. It is particularly useful in manufacturing, prototyping, landscaping, and architecture. This scanning technique measures the deformation of a straight line created by a cylindrical lens when it is incident into a non-flat surface. By using cameras and triangulation, it is possible to measure the changes in the shape of our laser line and therefore estimate the shape of the object that we are measuring. If you would like to learn more about Laser Line Scanning please leave a comment.

3. Laser Scanning Microscopy

They are usually used in combination with acousto-optic deflectors, where the focal point of a variable lens (the acousto-optical elements) can change its position laterally without the use of movable parts. The cylindrical lens corrects the image and helps focus the light spot onto the correct plane for laser scanning microscopy.

Q1:Can you send me free samples or Can i have an sample order ?

A: Yes, We accept sample orders, and we're also willing to send you free sample to test and check its quality . if we don't have the item in stock , then you could place an sample order.

Q2: How many days can i get my package after placing order?

A: If the order needs customized also the quantity is big. it will take around 10-30 wroking days to produce then shipping.

Q3: OEM services available?

A: Sure, please send us your design paper on platform to confirm more details information.

Q4:We have a commercial project,Can you help me offer an optical design solution ?

A:Yes, we have professional experts who are engaged in optical design for more than 25 years , please send us more detail of your project,we will supply our most suitable solutions for you.

Q5: What shipping methods do you have?

A: For small quanities or sample could by express such as: Fedex, UPS, DHL, EMS, etc. Large scale quantity in your demands:by sea/train ,or by air.In your requests.